| Test item(s) |

Test method(s) |

Test condition |

Requirement(s)(ASTM F1700-13a) |

Test result(s) |

| Length |

ASTM F2055-10 |

Specimen: 914mm×152mm, 5pcs Condition: 23±1 ℃ , 50±5%RH, 24h |

914.4mm±1.2mm |

Average:914mmDeviation from nominal size: -0.4mm |

| Width |

152.4mm±0.2mm |

Average: 2.94mm Deviation from nominal size:-0.18mm~+0.04mm |

| Squareness |

≤ 0.25mm |

Deviation range:0.00mm~+0.10mm |

| Thickness |

ASTM F386-11 |

Specimen: 152mm×152mm, 5pcs Condition:23±1 ℃ , 50±5%RH, 24h |

3.0mm±0.13mm |

Average: 2.94mm Deviation from

nominal size: -0.18mm~+0.04mm |

Thickness

of wear

layer |

ASTM F410-08(2013) |

Specimen: 13mm×50mm, 5pcs Condition: 23±2℃ , 50±5%RH,24h |

Commercial, Min 0.5mm |

Average: 0.315mm Maximum: 0.356mm

Minimum: 0.286mm |

Residual

indentation |

ASTM F1914-07(2011) |

Specimen: 51mm×51mm, 3pcs Diameter of indenter:4.521±0.0127mm Condition: 23±2℃ , 50±5%RH,24h → 140±1lb, 10min→Recovery time: 60min |

Average value:≤ 8% Maximum value:10% |

Average: 2.7% Maximum: 2.7% Minimum: 2.7% |

| Flexibility |

ASTM F137-08(2013) |

Specimen: Length direction,250mm×50mm, 3pcs,

Condition: 23±2℃ , 50±5%RH,24h The test piece is bent through 180º within 3s-5s around a mandrel under specified conditions. |

Test using a 25.4mm mandrel, no cracks or breaks |

When tested with a 25.4mm mandrel: Length direction, no cracks and breaks shown |

Dimensional

stability

(see note 2) |

ASTM F2199-09(2014) |

Specimen: 240mm×152mm, 3pcs

Condition: 23±2℃ , 50±5%RH,

24h →82±2℃ , 360min→23±2℃ , 50±5%RH, 24h |

≤0.51mm/305mm (≤ 0.17%) |

Length Direction:-0.10%

Width Direction:-0.07% |

Resistance

to

chemicals |

ASTM F925-13 |

Specimen: 914mm×152mm, 1pcs

Condition:23±2℃ , 50±5%RH, 24h Drop Method, Cover, 60±1min |

No more than a slight change in surface dulling, surface attack or

staining |

Rating 0:No change (See Table1) (see Note 3) |

Resistance

to heat |

ASTM F1514-03(2013) |

Specimen: 51mm×51mm, 3pcs

Condition: 23±1 ℃ , 50±5%RH,

24h →70±1 ℃ , 7days→23±1 ℃ , 50±5%RH, 24h |

Average ΔE*ab ≤ 8.0 |

Average ΔE*ab :0.09 (see Note 3) |

Light

stability |

ASTM F1515-15 & ASTM D2244-16 |

Exposure cycle:Irradiance: 0.30W/(m2•nm)@340nm ,Continuous light at (63±2) ℃ BPT,(50±10) %RH Filter: Window Exposure period: 300h |

Average ΔE*ab ≤ 8.0 |

Average ΔE*ab :1.1 (see note 4) |

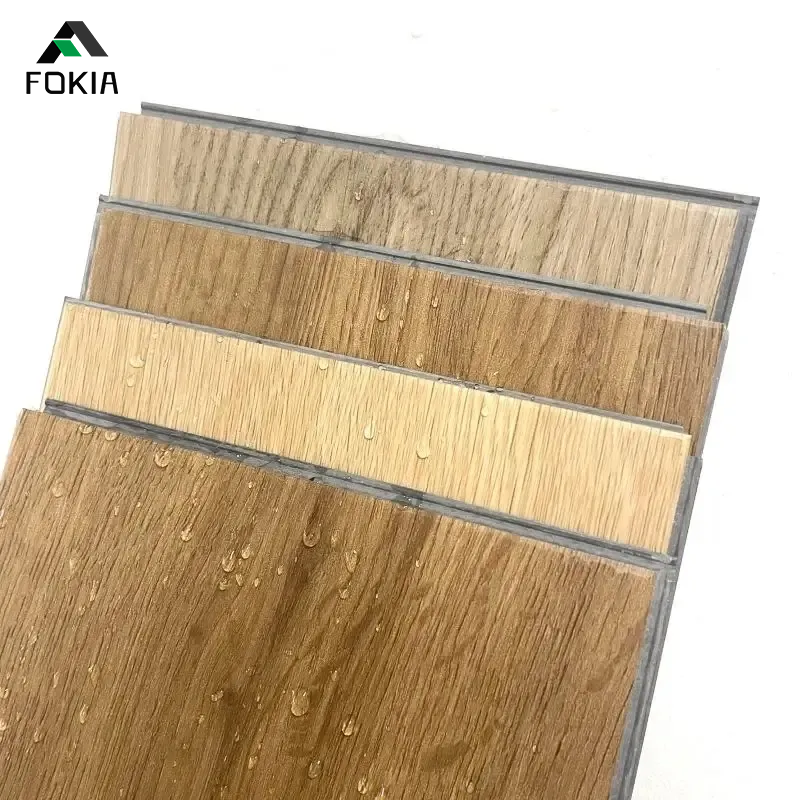

| Appearance |

ASTM F1700-13a Clause 7 |

Specimen: 914mm×152mm, 5pcs Condition:23±1 ℃ , 50±5%RH, 24h |

The product shall be free of defects which adversely affect performance or appearance. |

No visible defects |

Binder

content |

ASTM F1700-13a Clause 6.1 |

The binder contant shall bedetermined by statement of formula |

See Annex A |

Client’s statement See Annex A |