|

||

|

Product

|

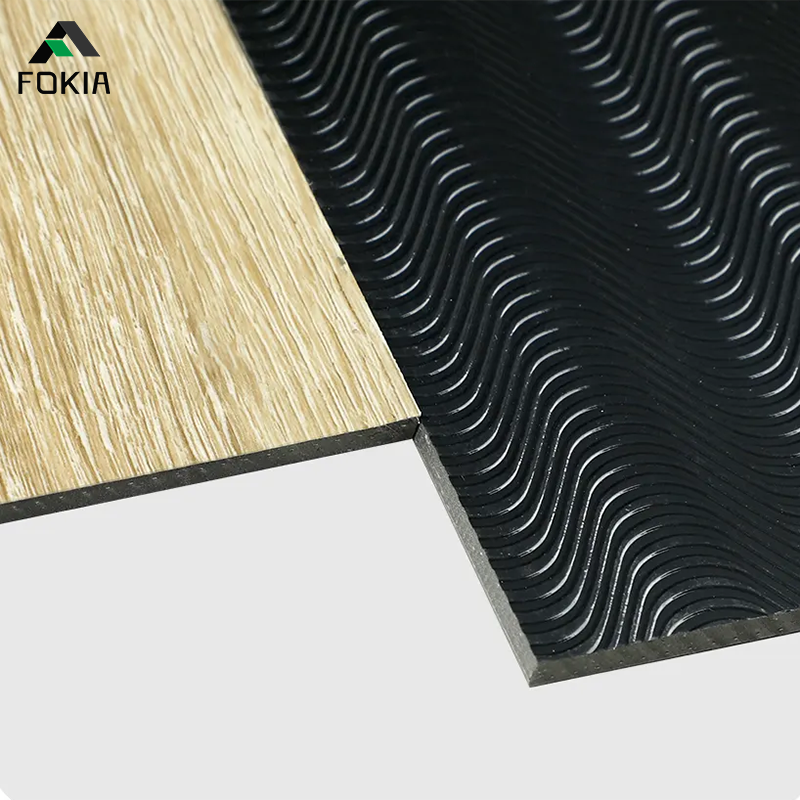

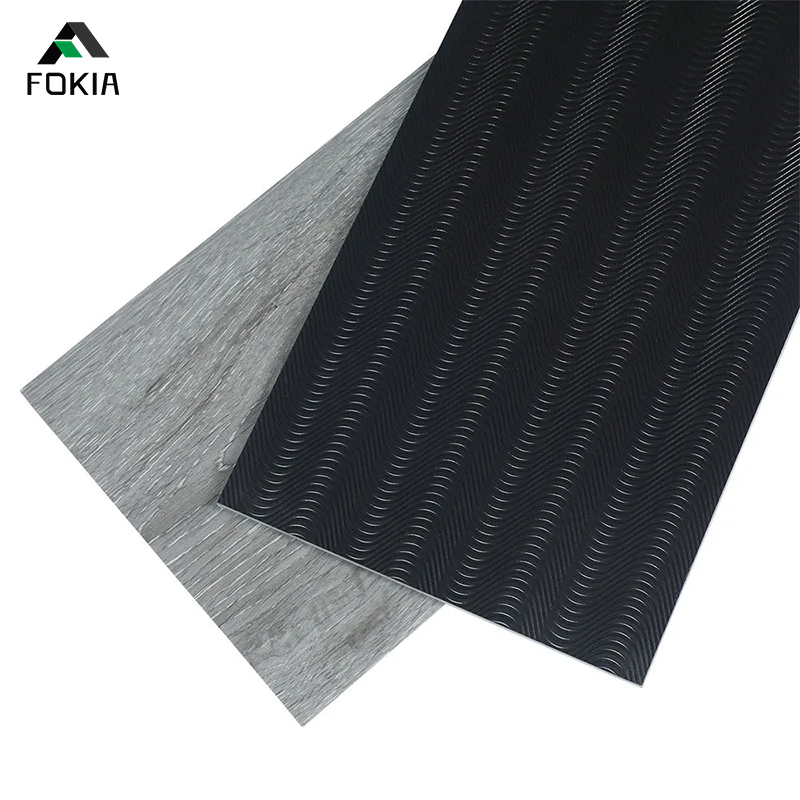

LVT Flooring / Luxury Vinyl Plank/ Luxury Vinyl Flooring

|

|

|

Thickness

|

4.0/4.5/5.0mm

|

|

|

Wear layer

|

0.2mm, 0.3mm, 0.5mm, 0.7mm

|

|

|

Features

|

Waterproof, Fireproof, Sound proof, Wear resistant

|

|

|

Useage

|

Bedroom, Kitchen, Landry, Hospital, Mall, School, etc

|

|

|

Loose lay lvt flooring size

|

Inch

|

mm

|

|

6”36”

|

152.4*914.4mm

|

|

|

6”48”

|

152.4*1219.2mm

|

|

|

7”48”

|

177.8*1219.2mm

|

|

|

9”48”

|

228.6*1219.2mm

|

|

|

18”18”

|

457.2*457.2mm

|

|

|

Surface texture

|

Stone Grain Wood Grain

|

|

Luxury vinyl flooring (LVT) offers the perfect combination of aesthetics, durability, and ease of installation. It replicates the look of natural timber, ceramic, or stone while surpassing hardwood in elasticity, impact resistance, wear resistance, and waterproofing.

| SEND PATTERN OR SAMPLES OF PRODUCTS TO US FOR CUSTOM PRODUCTION |

|

|

| Test item(s) | Test method(s) | Test condition | Requirement(s)(ASTM F1700-13a) | Test result(s) |

| Length | ASTM F2055-10 | Specimen: 914mm×152mm, 5pcs Condition: 23±1 ℃ , 50±5%RH, 24h | 914.4mm±1.2mm | Average:914mmDeviation from nominal size: -0.4mm |

| Width | 152.4mm±0.2mm | Average: 2.94mm Deviation from nominal size:-0.18mm~+0.04mm | ||

| Squareness | ≤ 0.25mm | Deviation range:0.00mm~+0.10mm | ||

| Thickness | ASTM F386-11 | Specimen: 152mm×152mm, 5pcs Condition:23±1 ℃ , 50±5%RH, 24h | 3.0mm±0.13mm | Average: 2.94mm Deviation from nominal size: -0.18mm~+0.04mm |

| Thickness of wear layer |

ASTM F410-08(2013) | Specimen: 13mm×50mm, 5pcs Condition: 23±2℃ , 50±5%RH,24h | Commercial, Min 0.5mm | Average: 0.315mm Maximum: 0.356mm Minimum: 0.286mm |

| Residual indentation |

ASTM F1914-07(2011) | Specimen: 51mm×51mm, 3pcs Diameter of indenter:4.521±0.0127mm Condition: 23±2℃ , 50±5%RH,24h → 140±1lb, 10min→Recovery time: 60min | Average value:≤ 8% Maximum value:10% | Average: 2.7% Maximum: 2.7% Minimum: 2.7% |

| Flexibility | ASTM F137-08(2013) | Specimen: Length direction,250mm×50mm, 3pcs, Condition: 23±2℃ , 50±5%RH,24h The test piece is bent through 180º within 3s-5s around a mandrel under specified conditions. |

Test using a 25.4mm mandrel, no cracks or breaks | When tested with a 25.4mm mandrel: Length direction, no cracks and breaks shown |

| Dimensional stability (see note 2) |

ASTM F2199-09(2014) | Specimen: 240mm×152mm, 3pcs Condition: 23±2℃ , 50±5%RH, 24h →82±2℃ , 360min→23±2℃ , 50±5%RH, 24h |

≤0.51mm/305mm (≤ 0.17%) | Length Direction:-0.10% Width Direction:-0.07% |

| Resistance to chemicals |

ASTM F925-13 | Specimen: 914mm×152mm, 1pcs Condition:23±2℃ , 50±5%RH, 24h Drop Method, Cover, 60±1min |

No more than a slight change in surface dulling, surface attack or staining |

Rating 0:No change (See Table1) (see Note 3) |

| Resistance to heat |

ASTM F1514-03(2013) | Specimen: 51mm×51mm, 3pcs Condition: 23±1 ℃ , 50±5%RH, 24h →70±1 ℃ , 7days→23±1 ℃ , 50±5%RH, 24h |

Average ΔE*ab ≤ 8.0 | Average ΔE*ab :0.09 (see Note 3) |

| Light stability |

ASTM F1515-15 & ASTM D2244-16 | Exposure cycle:Irradiance: 0.30W/(m2•nm)@340nm ,Continuous light at (63±2) ℃ BPT,(50±10) %RH Filter: Window Exposure period: 300h | Average ΔE*ab ≤ 8.0 | Average ΔE*ab :1.1 (see note 4) |

| Appearance | ASTM F1700-13a Clause 7 | Specimen: 914mm×152mm, 5pcs Condition:23±1 ℃ , 50±5%RH, 24h | The product shall be free of defects which adversely affect performance or appearance. | No visible defects |

| Binder content |

ASTM F1700-13a Clause 6.1 | The binder contant shall bedetermined by statement of formula | See Annex A | Client’s statement See Annex A |